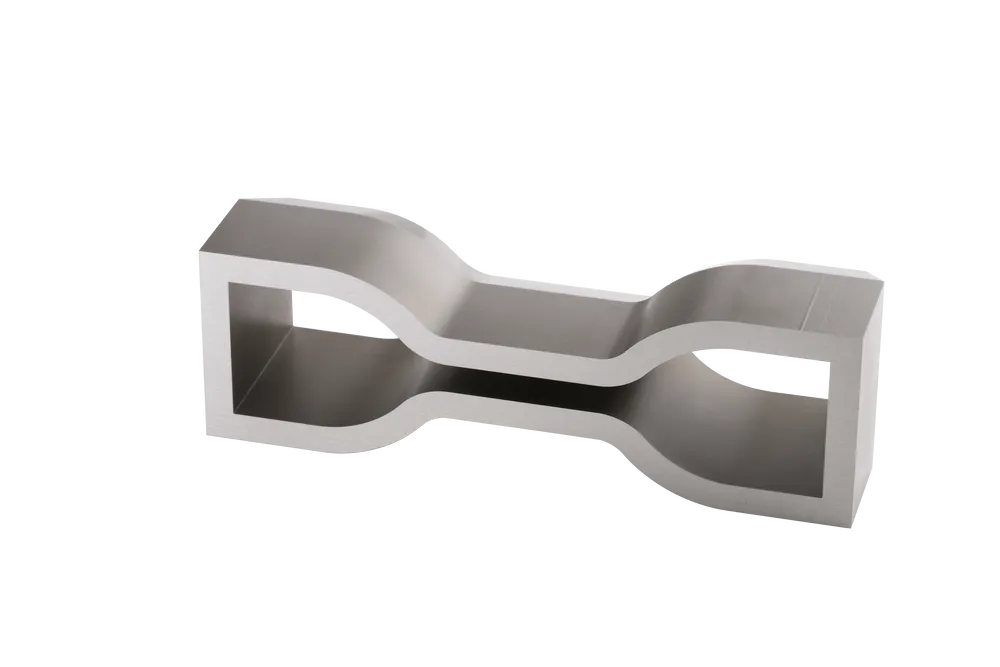

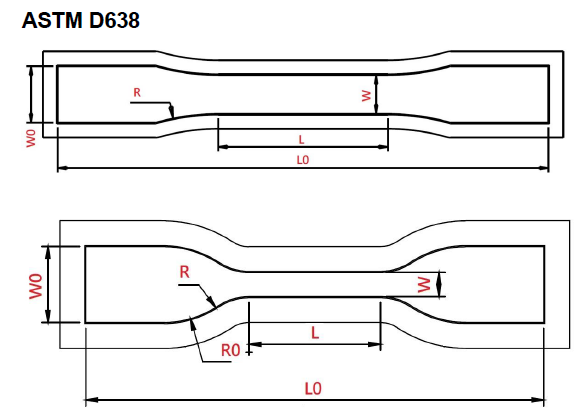

ASTM D638 – Dumbbell

ASTM D638 – Dumbbell

ASTM D638 is used to test the tensile properties of plastic materials, primarily measuring:

Test Parameters

- Tensile Strength – The maximum force a material can withstand under tension.

- Elongation at Break – The maximum extension ratio before rupture.

- Elastic Modulus – The material’s stiffness under tensile conditions.

Applications

Engineering Plastics – Used for testing electronic device housings and structural components.

Packaging Materials – Ensures the durability and flexibility of films and containers.

ASTM D638 is an internationally recognized standard for plastic tensile testing, widely used for evaluating the mechanical properties of engineering plastics, thermoplastics, and thermosetting materials. This test method is essential for material developers and quality engineers to understand the stress and deformation behavior of rigid plastic materials under load.

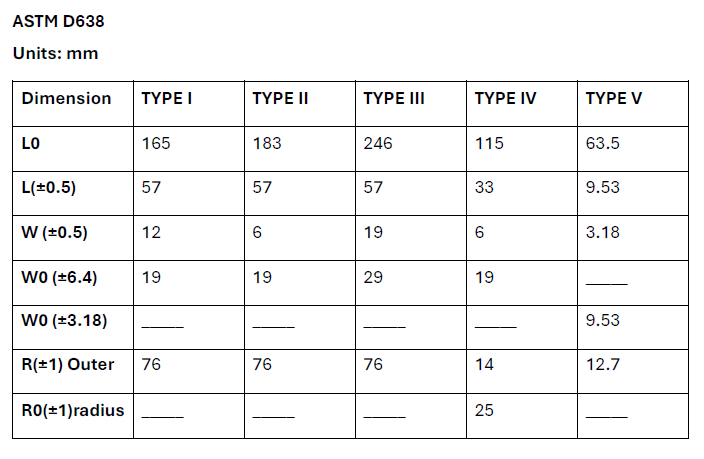

The test utilizes a standard dumbbell-shaped specimen and focuses on quantifying three key tensile properties:

-

Tensile Strength – The maximum stress a plastic material can withstand when stretched.

-

Elongation at Break – The percentage a material can elongate before breaking, indicating its flexibility and ductility.

-

Modulus of Elasticity – A measure of a material’s stiffness within the elastic deformation range.

As one of the most frequently applied tensile test standards for rubber and plastic materials, ASTM D638 is closely related to plastic tensile testers, cutting machines, and precision cutting dies. Accurate sample preparation—such as using ASTM D638-compliant specimen cutters—is critical for ensuring consistent and reliable test results.

Applicable Materials and Industry Applications

-

Engineering Plastics: Materials such as PC (Polycarbonate), PA (Polyamide/Nylon), ABS (Acrylonitrile Butadiene Styrene), and POM (Polyoxymethylene), commonly used in electronic components, automotive interiors, and structural parts.

-

Packaging Materials: Includes PE (Polyethylene), PP (Polypropylene), and PET (Polyethylene Terephthalate), widely applied in containers, films, packaging foils, and multi-layer composite structures.

-

Elastomeric Materials: Selected thermoplastic elastomers (TPEs) and soft plastics can also be tested using ASTM D638 for comparative tensile performance analysis.