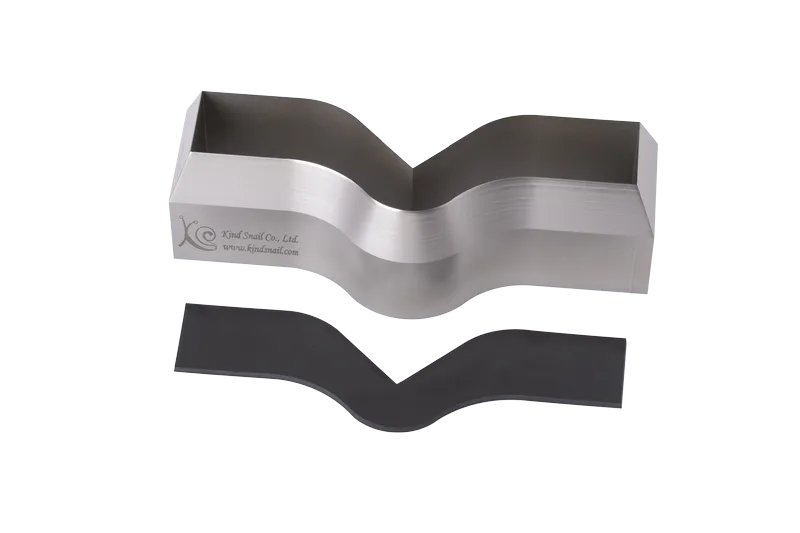

The Angle Rubber Cutter is designed for preparing standardized specimens used in tear strength testing, in compliance with international standards ISO 34-1 , ASTM D624 Die C and JIS K6252.

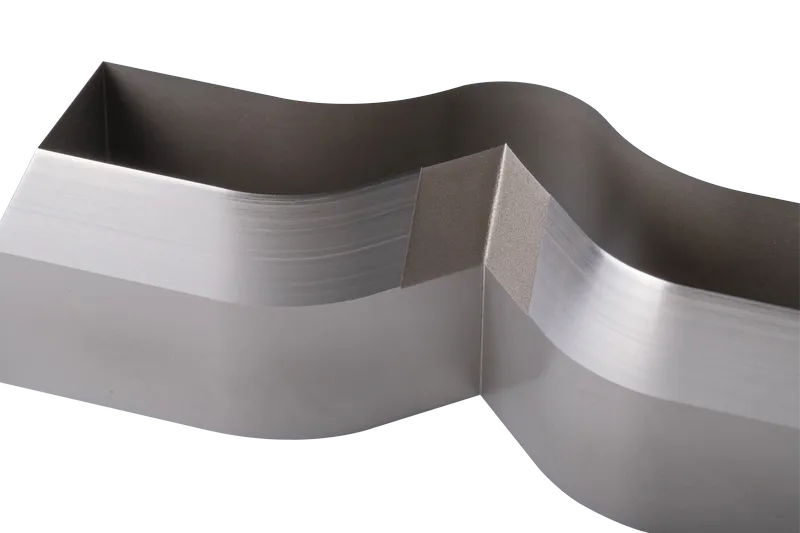

Its key feature—the right-angle notch—creates a defined stress-concentration point at a fixed position, ensuring a stable tear path and highly comparable test results.

This test evaluates a rubber material’s ability to resist crack initiation and propagation under stress and can be used to compare the influence of different formulations or vulcanization conditions.

Compared with other specimen geometries, the angle-type design more accurately simulates crack initiation at corners, edges, or joint sections, making it the most representative method for determining tear strength in rubber materials.

Applications of Angle Rubber Cutter

The Angle Rubber Cutter is widely used for preparing tear-strength test specimens of rubber and elastomer materials in accordance with ISO 34-1 , ASTM D624 Die C and JIS K6252 standards.

Beyond laboratory testing, it also serves research, product development, quality control, and material improvement processes.

Main Application Fields:

- Quality Control & Testing Laboratories – Preparation of standardized test specimens to establish reliable QC procedures.

- Research & Compound Evaluation – Analysis of the effects of formulation, fillers, or vulcanization systems on tear performance.

- Finished & Semi-finished Products –

• Footwear: Tear-strength testing of soles, heels, and air-cushion components.

• Tire & Hose Industry: Evaluation of tear resistance in sidewall, inner-liner, and hose materials.

• Sealing & Vibration Parts: Crack-propagation testing after long-term use.

• Rubberized Fabrics & Belts: Assessment of interlayer adhesion and reinforcement structure. - Academia & Comparative Studies – Investigation of crack-initiation and propagation mechanisms in various elastomer systems.

Testing Items and Data Significance

- Tear Strength Test

Specimens prepared with the Angle Rubber Cutter produce consistent tear paths at fixed notch locations. Using a tensile testing machine, the maximum force required to tear the specimen—from notch initiation to complete rupture—is recorded in N/mm, representing the material’s tear strength. - Crack Resistance Evaluation

Tear-strength data reveal the material’s ability to withstand crack initiation and propagation at high-stress points such as corners or edges. This serves as an important indicator of durability and structural integrity in rubber components. - Formulation and Process Analysis

Tear-strength results allow comparison of different formulations and process variables—such as reinforcing fillers (carbon black, silica, ZnO), vulcanization systems, or mixing parameters—supporting R&D optimization and quality improvement. - Quality and Design Reference

Stable tear-strength values indicate consistent processing and strong crack resistance. These results provide critical data for product design and quality assurance in soles, tires, seals, and conveyor-belt applications.

Advantages of Kind Snail Angle Rubber Cutter

- Integrated Alloy Tool Steel

Manufactured from high-strength alloy tool steel in a single-piece structure, ensuring dimensional precision, superior durability, and long-term cutting stability. - CNC Machining with EDM Finishing

Entirely processed by CNC precision machining, with Electrical Discharge Machining (EDM) applied at 90° corners to guarantee exact right-angle accuracy and consistent tear-test reproducibility. - Reinforced 5 mm Wall Thickness

A minimum wall thickness of 5 mm prevents deformation during specimen cutting, maintaining stable geometry and dimensional integrity. - Sharp and Uniform Cutting Edge

Finely ground cutting edges remain sharp and free from nicks or burrs, preventing serrated or rough specimen edges and ensuring reliable test accuracy.

Rubber Cutter Testing Procedures and Practical Considerations

The pneumatic cutting machine provided by Kind Snail enables fast and precise specimen preparation, ensuring consistency and efficiency. A manual cutting option is also available for flexible on-site operation.

★ All Kind Snail rubber testing equipment are compatible with various die shapes, supporting high-precision and high-efficiency cutting to enhance test consistency and productivity.

| Item | Pneumatic Cutting Machine | Manual Cutting Machine |

| Operational Stability | ✔ Consistent pressure, stable cutting quality | ▲Relies on manual force, less consistent |

| Cutting Efficiency | ✔ Suitable for high-volume, continuous preparation | ▲Suitable for low-frequency or small-batch testing |

| Operator Fatigue | ✔ Low effort, ideal for extended testing use | ▲More tiring with prolonged operation |

| Maintenance | ▲ Requires air supply | ✔ Simple structure, easy to maintain and move |

Regardless of the cutting method used, specimen quality must meet standard requirements, including smooth edges, uniform thickness, and precise geometry. Poorly prepared specimens may lead to stress concentration during testing, compromising the accuracy and repeatability of tensile results.

In addition, the following factors should be carefully monitored during testing:

- Clamping force and alignment of grips: Ensure the specimen is held securely and symmetrically in the testing machine to avoid slippage or uneven breakage.

- Specimen cutting quality: Edges should be clean, thickness uniform, and geometry accurate. Burrs or shape deviations may cause uneven stress distribution, resulting in unreliable tensile data.

Pneumatic Specimen Cutter – Video Overview

Conclusion

The Angle Rubber Cutter is not only a standard tool for preparing tear-strength specimens but also a reflection of our commitment to testing precision, result consistency, and product quality control.

With advanced manufacturing and material expertise, Kind Snail Co., Ltd. ensures every cutter delivers traceable and repeatable performance—helping laboratories and manufacturers achieve dependable results in research, quality evaluation, and international certification.