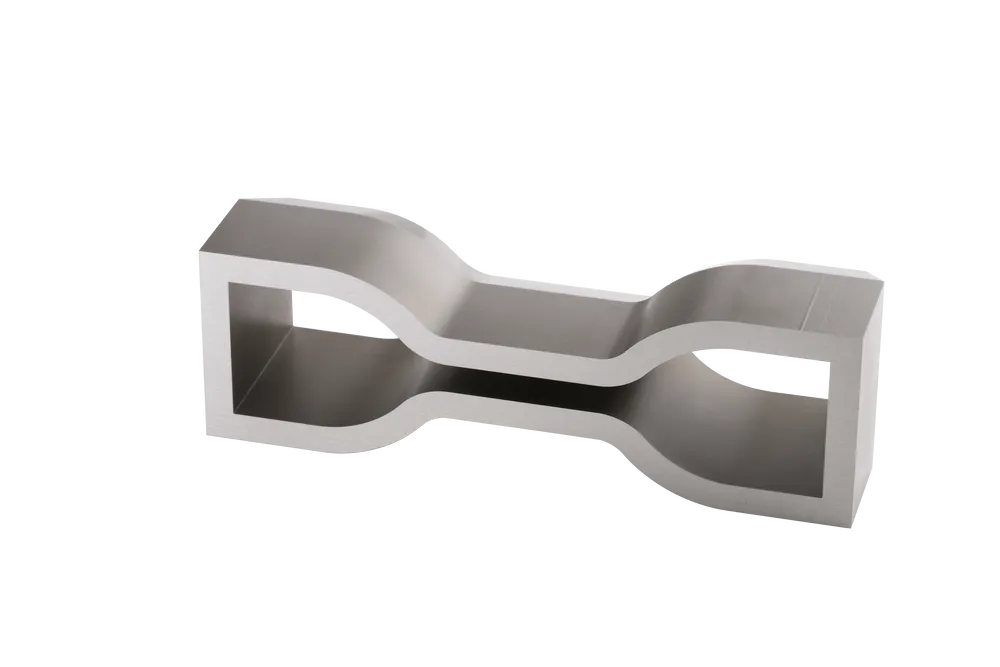

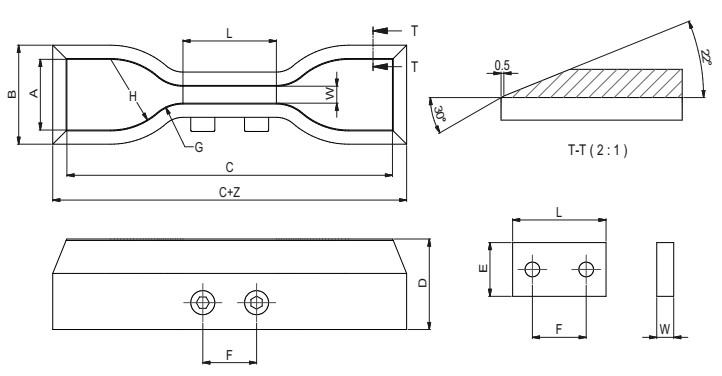

ASTM D412 – Dumbbell

ASTM D412 – Dumbbell

ASTM D412 is used to test the tensile properties of rubber and elastomeric materials, primarily measuring:

Test Parameters

- Tensile Strength – The material’s ability to withstand high tensile forces.

- Elongation at Break – The stretching behavior of rubber before rupture.

- Stress-Strain Behavior – The deformation characteristics under different stress levels.

Applications

Tires & Sealing Rings – Ensures reliability and elasticity in high-load environments.

Industrial Rubber Products – Evaluates the strength and durability of transmission belts and hoses.

ASTM D412 is a globally recognized standard for evaluating the tensile properties of vulcanized rubber and thermoplastic elastomers (TPEs). It is widely applied in assessing the mechanical behavior of flexible and elastic materials, helping product developers and quality engineers understand how materials perform under tensile stress and deformation during actual use.

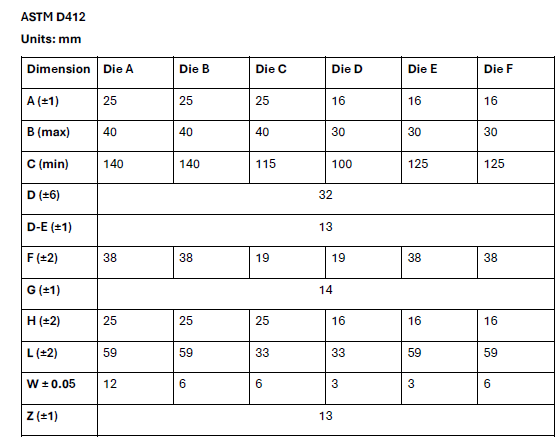

During the test, standard dumbbell-shaped specimens (typically Die C) are stretched to failure using a rubber tensile tester, and the following key mechanical properties are measured:

- Tensile Strength – The maximum tensile stress a material can withstand before breaking.

- Elongation at Break – The strain or elongation percentage a material undergoes before rupture, reflecting its flexibility and ductility.

- Tensile Stress at Specific Elongation – Stress levels recorded at defined elongations (e.g., 100%, 200%, 300%) to analyze stress-strain behavior under various conditions.

- Tensile Set (Permanent Deformation) – The amount of residual deformation remaining after a specimen is stretched and then allowed to recover.

As one of the most widely used rubber tensile test standards, ASTM D412 is closely linked to testing instruments and accessories used in elastomer quality control, including tensile testing machines, precision cutting dies, and ASTM D412 specimen cutters. Accurate specimen preparation according to the standard (such as using Die C cutters) is essential to ensure data consistency and comparability across tests.

Applicable Materials and Industry Applications:

- Industrial Rubber: Including NR, NBR, EPDM, FKM – used in seals, hoses, gaskets, and vibration control parts.

- Thermoplastic Elastomers (TPEs): Such as TPU, TPE-S, and TPE-O – found in overmolded grips, sporting goods, and consumer electronics.

- Medical and Consumer Rubber Goods: Latex gloves, silicone tubing, and elastic straps for face masks, requiring high tensile and elongation performance.